ANNISTON HEALTH AND REHAB SERVICES

Over 2 years since last inspection. Current conditions may differ from available data.

Anniston Health and Rehab Services has a Trust Grade of B, indicating it is a good choice among nursing homes, though not the very best. It ranks #81 out of 223 facilities in Alabama, placing it in the top half, and #2 out of 5 in Calhoun County, meaning only one local option is better. The facility's trend is stable, with the same number of issues reported in both 2019 and 2021. Staffing is a strength here, with a 4 out of 5-star rating and a turnover rate of 43%, which is lower than the Alabama average. Although the facility has not incurred any fines, there are some concerns, such as failures to ensure proper food sanitization practices and the safe storage of medical equipment, which could potentially affect residents' health.

- Trust Score

- B

- In Alabama

- #81/223

- Safety Record

- Low Risk

- Inspections

- Holding Steady

- Staff Stability ○ Average

- 43% turnover. Near Alabama's 48% average. Typical for the industry.

- Penalties ✓ Good

- No fines on record. Clean compliance history, better than most Alabama facilities.

- Skilled Nurses ✓ Good

- Each resident gets 53 minutes of Registered Nurse (RN) attention daily — more than average for Alabama. RNs are trained to catch health problems early.

- Violations ✓ Good

- Only 4 deficiencies on record. Cleaner than most facilities. Minor issues only.

The Good

-

4-Star Staffing Rating · Above-average nurse staffing levels

-

Full Sprinkler Coverage · Fire safety systems throughout facility

-

No fines on record

-

Staff turnover below average (43%)

5 points below Alabama average of 48%

Facility shows strength in staffing levels, fire safety.

The Bad

Near Alabama average (2.9)

Meets federal standards, typical of most facilities

Near Alabama avg (46%)

Typical for the industry

Part of a multi-facility chain

Ask about local staffing decisions and management

The Ugly 4 deficiencies on record

Dec 2021

2 deficiencies

CONCERN

(D)

Potential for Harm - no one hurt, but risky conditions existed

Respiratory Care

(Tag F0695)

Could have caused harm · This affected 1 resident

**NOTE- TERMS IN BRACKETS HAVE BEEN EDITED TO PROTECT CONFIDENTIALITY** Based on observation, interview, record review, and review of a facility policy titled Medication Administration of Nose Drop; E...

Read full inspector narrative →

CONCERN

(F)

Potential for Harm - no one hurt, but risky conditions existed

Food Safety

(Tag F0812)

Could have caused harm · This affected most or all residents

Based on observation, interview and review of a facility policy titled Cleaning of Miscellaneous Equipment and Utensils and review of the Food Code 2017, the facility failed to ensure pans were allowe...

Read full inspector narrative →

Jun 2019

2 deficiencies

CONCERN

(D)

Potential for Harm - no one hurt, but risky conditions existed

Medical Records

(Tag F0842)

Could have caused harm · This affected 1 resident

**NOTE- TERMS IN BRACKETS HAVE BEEN EDITED TO PROTECT CONFIDENTIALITY** Based on record review and an interview with facility staff, the facility failed to ensure licensed staff clarified medication o...

Read full inspector narrative →

CONCERN

(F)

Potential for Harm - no one hurt, but risky conditions existed

Food Safety

(Tag F0812)

Could have caused harm · This affected most or all residents

Based on observations, interviews, review of facility policies: Dish Machine Sanitization, and Food Preparation Principles, as well as an Ecolab service report, the facility failed to ensure:

1) the d...

Read full inspector narrative →

Understanding Severity Codes (click to expand)

Questions to Ask on Your Visit

- "Can I speak with families of current residents?"

- "What's your RN coverage like on weekends and overnight?"

Our Honest Assessment

- • No major safety red flags. No abuse findings, life-threatening violations, or SFF status.

- • No fines on record. Clean compliance history, better than most Alabama facilities.

- • Only 4 deficiencies on record. Cleaner than most facilities. Minor issues only.

- • 43% turnover. Below Alabama's 48% average. Good staff retention means consistent care.

- • No major red flags. Standard due diligence and a personal visit recommended.

About This Facility

What is Anniston Health And Rehab Services's CMS Rating?

CMS assigns ANNISTON HEALTH AND REHAB SERVICES an overall rating of 3 out of 5 stars, which is considered average nationally. Within Alabama, this rating places the facility higher than 99% of the state's 100 nursing homes. This mid-range rating indicates the facility meets federal standards but may have areas for improvement.

How is Anniston Health And Rehab Services Staffed?

CMS rates ANNISTON HEALTH AND REHAB SERVICES's staffing level at 4 out of 5 stars, which is above average compared to other nursing homes. Staff turnover is 43%, compared to the Alabama average of 46%. This relatively stable workforce can support continuity of care.

What Have Inspectors Found at Anniston Health And Rehab Services?

State health inspectors documented 4 deficiencies at ANNISTON HEALTH AND REHAB SERVICES during 2019 to 2021. These included: 4 with potential for harm.

Who Owns and Operates Anniston Health And Rehab Services?

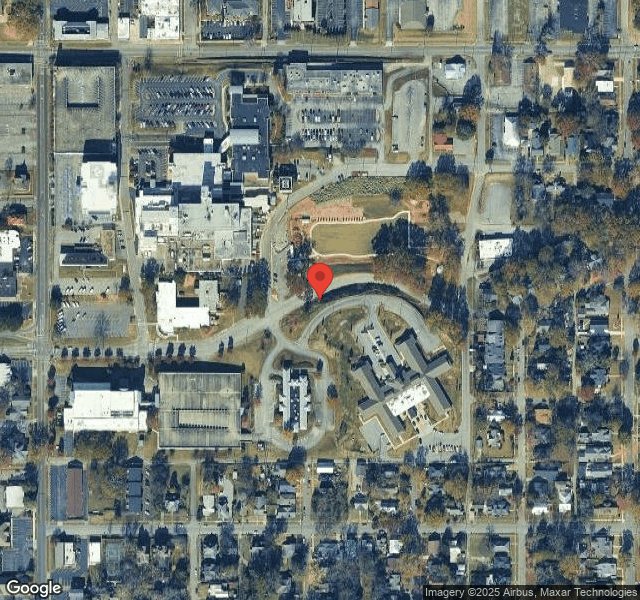

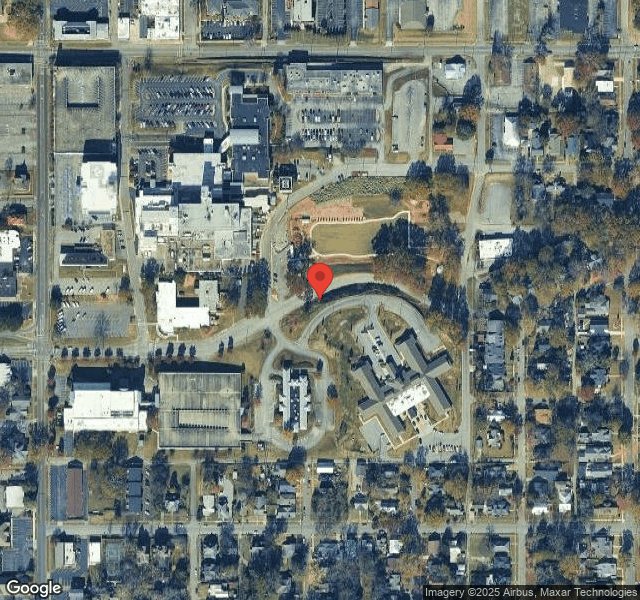

ANNISTON HEALTH AND REHAB SERVICES is owned by a non-profit organization. Non-profit facilities reinvest revenue into operations rather than distributing to shareholders. The facility is operated by NOLAND HEALTH, a chain that manages multiple nursing homes. With 85 certified beds and approximately 75 residents (about 88% occupancy), it is a smaller facility located in ANNISTON, Alabama.

How Does Anniston Health And Rehab Services Compare to Other Alabama Nursing Homes?

Compared to the 100 nursing homes in Alabama, ANNISTON HEALTH AND REHAB SERVICES's overall rating (3 stars) is above the state average of 2.9, staff turnover (43%) is near the state average of 46%, and health inspection rating (3 stars) is at the national benchmark.

What Should Families Ask When Visiting Anniston Health And Rehab Services?

Based on this facility's data, families visiting should ask: "Can I visit during a mealtime to observe dining assistance and food quality?" "How do you handle medical emergencies, and what is your hospital transfer rate?" "Can I speak with family members of current residents about their experience?"

Is Anniston Health And Rehab Services Safe?

Based on CMS inspection data, ANNISTON HEALTH AND REHAB SERVICES has a clean safety record: no substantiated abuse findings (meaning no confirmed cases of resident harm), no Immediate Jeopardy citations (the most serious violation level indicating risk of serious injury or death), and is not on the Special Focus Facility watch list (a federal program monitoring the lowest-performing 1% of nursing homes). The facility has a 3-star overall rating and ranks #1 of 100 nursing homes in Alabama. While no facility is perfect, families should still ask about staff-to-resident ratios and recent inspection results during their visit.

Do Nurses at Anniston Health And Rehab Services Stick Around?

ANNISTON HEALTH AND REHAB SERVICES has a staff turnover rate of 43%, which is about average for Alabama nursing homes (state average: 46%). Moderate turnover is common in nursing homes, but families should still ask about staff tenure and how the facility maintains care continuity when employees leave.

Was Anniston Health And Rehab Services Ever Fined?

ANNISTON HEALTH AND REHAB SERVICES has no federal fines on record. CMS issues fines when nursing homes fail to meet care standards or don't correct problems found during inspections. The absence of fines suggests the facility has either maintained compliance or corrected any issues before penalties were assessed. This is a positive indicator, though families should still review recent inspection reports for the full picture.

Is Anniston Health And Rehab Services on Any Federal Watch List?

ANNISTON HEALTH AND REHAB SERVICES is not on any federal watch list. The most significant is the Special Focus Facility (SFF) program, which identifies the bottom 1% of nursing homes nationally based on persistent, serious quality problems. Not being on this list means the facility has avoided the pattern of deficiencies that triggers enhanced federal oversight. This is a positive indicator, though families should still review the facility's inspection history directly.